PROCESSING

Tradition and technology The techniques used in the various crushers for the different phases of olive processing can be totally linked to tradition, can combine traditional elements to modern systems, or inspire themselves throughout and throughout the most sophisticated technologies; It is now ascertained that the quality of extra virgin olive oil depends on a verse from the characteristics of olives, from their cultivars and collection systems, for each other by extraction technology, especially by machines used and from the use of themselves .

The phases are:

Storage and weighing arrived at the crusher, the olives collected are first of all placed in special cassettes with side hurryings, allowing the air circulating within containers and avoiding that they deteriorate.

The phases are:

Storage and weighing arrived at the crusher, the olives collected are first of all placed in special cassettes with side hurryings, allowing the air circulating within containers and avoiding that they deteriorate.

Defoliation The olives are cleaned by means of a foliage defoliator, twigs, stones, earth and other impurities, together with the olives after harvesting.

Washing is carried out in modern plants by immersion of olives in special washing machines that maintain a forced handling of water in order to eliminate residues and plant impurities and minerals; To obtain a quality oil, at this stage it is also important that the water used is clean by reciprocating it frequently; At the end of the operation the olives suffer a drying for simple flushing water of washing.

Washing is carried out in modern plants by immersion of olives in special washing machines that maintain a forced handling of water in order to eliminate residues and plant impurities and minerals; To obtain a quality oil, at this stage it is also important that the water used is clean by reciprocating it frequently; At the end of the operation the olives suffer a drying for simple flushing water of washing.

Crushing

The same washed olives are automatically transported by a bearer tape into a mechanical hammer mill: fringe, from which the name crusher, literally means breaking, crush the olives, the peel and the core; An olive paste is obtained, followed by an intense and pleasant aroma that circumscribes the whole crusher, which is sent to the grammole.

The same washed olives are automatically transported by a bearer tape into a mechanical hammer mill: fringe, from which the name crusher, literally means breaking, crush the olives, the peel and the core; An olive paste is obtained, followed by an intense and pleasant aroma that circumscribes the whole crusher, which is sent to the grammole.

Gramozione or Gramlature

The gram or grazing process is extremely important for the yield and quality of the oil; The decisive parameters are the experience of the Frantoiano, the type of cultivar, the time of permanence (not exceeding 60 minutes) and the temperature (not exceeding 27-28 ° C): it, removing continuously the olive paste Coming from pressing and placed in machines that grammole or gram, aims to break the emulsion between vegetation water and oil and allow small drops of oil to join between them in greater drops (the Aggregation) that tend to separate themselves spontaneously from the water.

The gram or grazing process is extremely important for the yield and quality of the oil; The decisive parameters are the experience of the Frantoiano, the type of cultivar, the time of permanence (not exceeding 60 minutes) and the temperature (not exceeding 27-28 ° C): it, removing continuously the olive paste Coming from pressing and placed in machines that grammole or gram, aims to break the emulsion between vegetation water and oil and allow small drops of oil to join between them in greater drops (the Aggregation) that tend to separate themselves spontaneously from the water.

Extraction

Today is operating in almost all the crushers the continuous extraction system for centrifugation (three or two phases, with recycling of vegetation water), a compact system in which all the processing phases take place without manipulation and with the slightest intervention of the Man: On the one hand the olive enters, the oil comes out. After grazing the olive paste is mixed with a 30% water at a controlled temperature and transferred to be subjected, without interruption, to a centrifugation in a rotating conical drum with a horizontal axis called DECANTER, whose rotation speed is 3000- 3500 rpm; Through the physical principle of the separation of a product composed of several elements to different specific weight, due to the centrifugal force, it is separated in phases, from which the Sansa (the pulp and the hazel of the frantium olives come out), oil and The vegetation water (three-way decanter) or only oil and vegetation water (two-way decanter).

Separation

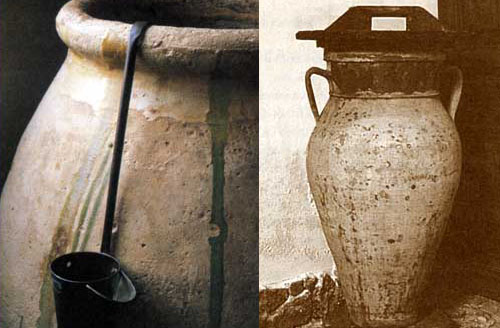

to end the process it is necessary to totally separate the oil from the vegetation water and for further impurities; To do this, a vertical centrifugal extractor said separator is used; This oil is named "cold extract" as it does not exceed 27-28 ° C in the gram / extraction phase; The olive oil rendering varies from cultivar to cultivar: the whitelilla on kg. 100 of olives produces lt. 17-18 of oil. Storage The latest processing phase takes place by putting extra virgin olive oil in stainless steel containers, located in dark and fresh rooms away from heat and light sources. After the rigorously natural decantation lasting thirty days, the oil is bottled and marketed.

Today is operating in almost all the crushers the continuous extraction system for centrifugation (three or two phases, with recycling of vegetation water), a compact system in which all the processing phases take place without manipulation and with the slightest intervention of the Man: On the one hand the olive enters, the oil comes out. After grazing the olive paste is mixed with a 30% water at a controlled temperature and transferred to be subjected, without interruption, to a centrifugation in a rotating conical drum with a horizontal axis called DECANTER, whose rotation speed is 3000- 3500 rpm; Through the physical principle of the separation of a product composed of several elements to different specific weight, due to the centrifugal force, it is separated in phases, from which the Sansa (the pulp and the hazel of the frantium olives come out), oil and The vegetation water (three-way decanter) or only oil and vegetation water (two-way decanter).

Separation

to end the process it is necessary to totally separate the oil from the vegetation water and for further impurities; To do this, a vertical centrifugal extractor said separator is used; This oil is named "cold extract" as it does not exceed 27-28 ° C in the gram / extraction phase; The olive oil rendering varies from cultivar to cultivar: the whitelilla on kg. 100 of olives produces lt. 17-18 of oil. Storage The latest processing phase takes place by putting extra virgin olive oil in stainless steel containers, located in dark and fresh rooms away from heat and light sources. After the rigorously natural decantation lasting thirty days, the oil is bottled and marketed.